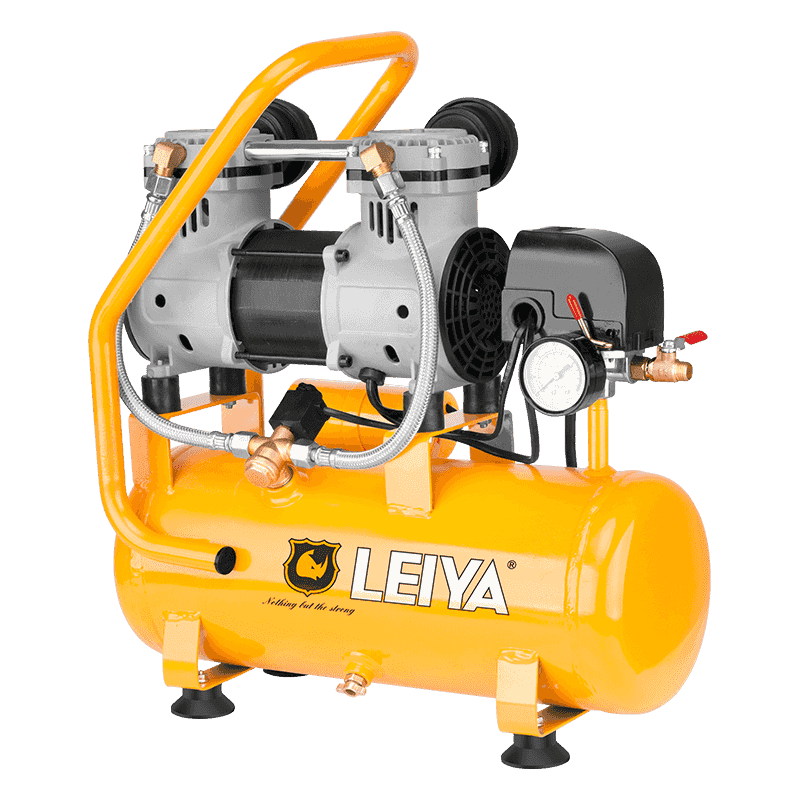

Oil-free compressor is a common air compressor that does not require the use of oil lubricants, but is manufactured using special materials and processes, with the following characteristics:

1. Environmental protection and cleaning: Oil-free compressors do not require the use of oil lubricants and do not produce oil mist and dirt. They are very suitable for occasions that require pure gas and have no pollution to air quality.

2. Simple maintenance: The oil-free compressor has a long service life, simple maintenance, and reduces cost and time waste.

3. More stable operation: The internal components of the oil-free compressor are specially designed and processed to be more durable, able to maintain high-speed and stable operation, and will not be damaged or malfunctioned due to a lack of lubricating oil like oil compressors.

4. Low noise: Oil-free compressors have low noise, which can reduce interference to the surrounding environment and users.

The main application scenarios of oil-free compressors include:

1. Medical field: The output gas of the oil-free compressor is clean and oil-free, making it very suitable for respiratory therapy, oxygen inhalation, and other occasions in the medical field that require high-quality pure oxygen.

2. Semiconductor industry: semiconductor production needs a clean gas environment, and oil-free compressors are very suitable for providing clean and stable air pressure.

3. Food processing: In food processing plants, pure gas environment is required. The oil-free compressor is suitable for the fields of modified atmosphere packaging, Bottled water compression, etc.

4. Industrial manufacturing: Oil-free compressors can be used in fields such as plastic suction and compressed gas cleaning in conjunction with other equipment.

The characteristics of oil-free compressors make them essential equipment in medical, semiconductor, food, and industrial fields. They provide new solutions for production and processing, improving work efficiency and product quality.

English

English Deutsch

Deutsch русский

русский 中文简体

中文简体 عربى

عربى Español

Español

+86(579) 8796 5708

+86(579) 8796 5708