- Home

- About Us

- Product

- Cordless Power Tools

- Corded Power Tools

- Angle Grinder

- Corded Impact Drill

- Wall Chaser

- Cut-Off Machine

- Waterproofing Machine

- Trimmer Router

- Electric Blower

- Jig Saw

- Rotary Hammer

- Direct Driven Compressor

- Electric Drill

- Marble Cutter

- Circular Saw

- Miter Saw

- Diamond Drill Machine

- Electric Sander

- Electric Planer

- Electric Router

- Demolition Hammer

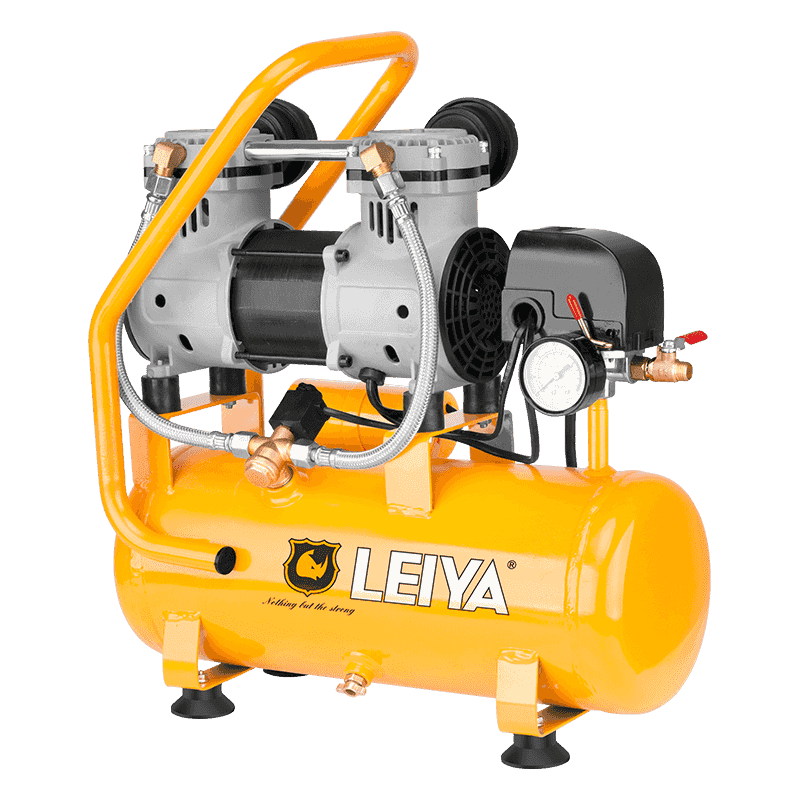

- Oil-Free Compressor

- Capacity

- News

- Contact Us

English

English Deutsch

Deutsch русский

русский 中文简体

中文简体 عربى

عربى Español

Español

++86(579) 8796 5708

++86(579) 8796 5708